Recognizing the Function of Heat Transfer Fluid in Effective Energy Equipments

Why Warmth Transfer Fluid Is Essential for Optimizing Energy Transfer in Systems

The function of warm transfer liquids in enhancing energy transfer is critical for attaining reliable thermal monitoring across different commercial industries. These liquids help with seamless warmth exchange, ensuring processes operate within ideal temperature level varieties and reducing the danger of getting too hot.

Duty in Thermal Management

Warmth transfer liquids play an essential duty in thermal administration by effectively controling temperature levels in various commercial processes and systems. These specialized fluids assist in the transfer of warm between different parts, making certain optimal operating conditions and protecting against overheating. By preserving exact temperature level control, warmth transfer fluids enable sectors such as chemical manufacturing, oil and gas, and power generation to run securely and efficiently.

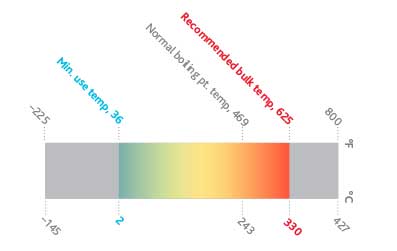

The option of a proper warmth transfer liquid depends upon numerous variables, including thermal security, warmth ability, and thickness. High thermal stability guarantees that the liquid can stand up to extreme temperatures without breaking down, while a high warm capability enables it to absorb and release substantial quantities of warm - heat transfer fluid. Reduced thickness lowers the energy required for pumping, contributing to overall system effectiveness

Furthermore, warmth transfer liquids are essential in applications like refrigeration, where they assist soak up and dissipate heat throughout the cooling cycle. In solar thermal power systems, these liquids capture and transport solar warm to produce power or provide hot water. Their versatility to varied operating conditions and capability to maintain consistent thermal efficiency highlight their importance in industrial thermal management, helping with operational continuity and enhancing precaution.

Enhancing System Effectiveness

To take full advantage of the benefits of thermal management, enhancing system performance via the tactical usage of heat transfer liquids is vital. By keeping ideal temperature level levels, warm transfer fluids help make certain that systems run within their made parameters, therefore avoiding overheating and lowering the threat of component failure.

Types of Heat Transfer Liquids

The diversity of warm transfer liquids emphasizes their vital role in a range of industrial applications, each customized to satisfy specific thermal administration needs. These liquids facilitate effective energy transfer and are selected based upon key properties such as thermal stability, thickness, and warm ability. The key kinds consist of water, glycol services, oils, and synthetics, each offering unique advantages.

Water is the most typical heat transfer tool due to its high certain warm capability and reduced expense. Mineral oils are preferred for their thermal security and non-corrosive nature, making them suitable for high-temperature applications.

These fluids ensure remarkable efficiency in systems where typical liquids might stop working. The option of a warmth transfer liquid is vital, as it affects system performance, safety and security, and longevity.

Environmental and Economic Benefits

Using the right warm transfer liquids offers substantial environmental and economic benefits for industrial procedures. Eco pleasant warmth transfer fluids, usually biodegradable and safe, lessen the threat of dirt and water contamination in the event of leaks or spills, therefore securing communities and conforming with strict ecological policies.

Economically, the click here now ideal heat transfer fluid can dramatically decrease operational costs. Effective warm transfer lowers power expenditure, resulting in reduced utility expenses visit our website and enhanced profitability. Fluids with prolonged lifecycle efficiency decrease the regularity of replacements and upkeep, minimizing downtime and connected costs. Purchasing high-grade fluids can likewise mitigate the danger of equipment rust and failure, avoiding expensive repairs and extending the life-span of crucial framework. In open markets, these savings and performances provide a distinct benefit, enabling companies to allot sources better and purchase further technology. On the whole, the critical usage of ideal heat transfer liquids sustains lasting financial growth and environmental stewardship.

Picking the Right Liquid

Exactly how does one browse the intricate procedure of choosing the ideal heat transfer fluid for commercial applications? Selecting the ideal liquid is important, as it straight influences system performance, security, and functional costs. Key factors to consider consist of thermal security, compatibility with system materials, and running temperature range. Thermal security guarantees the liquid can endure high temperature levels without breaking down, while compatibility avoids deterioration or other damaging responses with system parts. The operating temperature level range need to line up with the system's requirements to keep performance and longevity - heat transfer fluid.

Additionally, the fluid's warmth capability and thickness are critical. A high warmth capacity enables the fluid to absorb and move even more power, enhancing efficiency.

Final Thought

The critical option a fantastic read and application of warm transfer liquids are fundamental to optimizing energy transfer throughout various systems. By making sure high thermal security and capacity, these liquids supply exact temperature control and boost general system effectiveness. This optimization adds to lowered operational expenses and reduced greenhouse gas emissions, thus promoting sustainability. The selection of fluid, tailored to specific viscosity and functional demands, is crucial for making the most of performance and accomplishing financial and ecological benefits in industrial processes.